Wetmix Macadam Plants

- Full-Circulating Spray bar.

- A unique pressure cleaning system provided.

- Engine Compartment: Air Cooled diesel engine and positive displacement gear pump.

- Fully-insulated tank with high performance oil heating.

- Operator's Platform for all functions of the machine.

The Feeding System for Cement Treated Agregate (Optional)

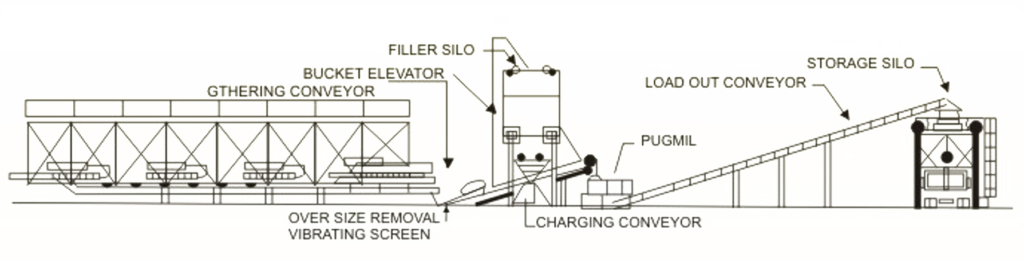

A filter silo unit of40 MT Capacity with a bucket elevator arrangement for receiving fines (cement/lime) from bags. A rotary metering valve coupled with a high efficiency screw conveyor delivers the specified quantity of fines to the pug mill unit.

CONTROL AND AUTOMATION

The weather protected cabin houses the user-friendly controls are specifically designed for industrial installations The logically laid out various control panel ensures seuqeuntion operation of the overrids in the form of a push button located close to the pug mill unit affords additional safety.

STORAGE SILO

The 25 MT Stoarge silo (Optional some models) is rigid, easy to erect and transfer. The batcher arrangment at the feeding point minimises mix segregation fast opening hydrauli-cally operated clamshell gates facilitate quick discharge of mix materials into thetruck without segregation.

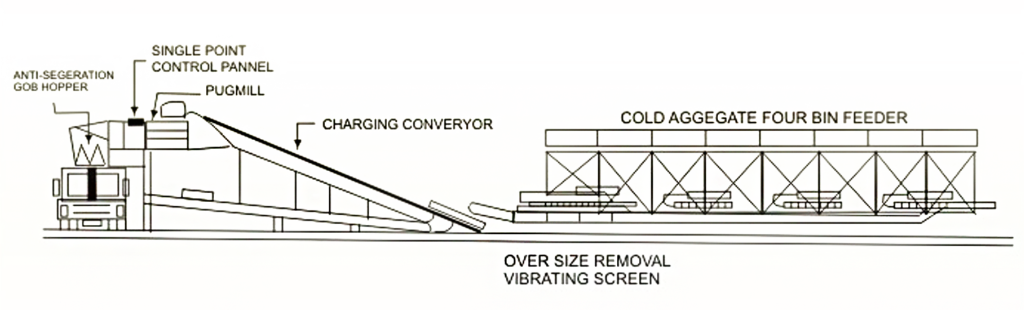

COLD FEED BINS

The bins are all welded and modular in construction, permitting easy addition of bins to meet growing needs. Steep bin walls and valley angles allows free flow of aggregates from the feeders minimising hang up of materials in the comers and briding with sticky aggregates. The bins are equipped with adjustable gates. The belt feeders can have either fixed or varibable spped drives. The optional variable spped drive coupled with total and proportional 'control offers greater flexibility and accuracy of corners.

PUG MILL UNIT

The twin shaft pug mill design providers fasts, continuous and homogeneous mixing of aggregates and additives / The shafts are mounted on extra heavy duty anti-friction bearing for smooth function and extended life. The wear resistant alloy steel selection for paddle arm and tips, lowers maintenance cost. The liner plates are corrosion and abrasion resistant.

WATER TANKS & METERING

The water tank has adequate surge capacity, self-priming pump, control valve and spray bar with water flow meter for accurate metering. A cleaning arrangement with flexible piping is a thoughtful add on.

Salient Features:

- ISO 9001-2000 Certified Company.

- Easy to operate.

- Modern central Mix Stationary/Mobile Plant.

- Lower Capital & operation costs.

- Uniform mixing and deli every of mixed material without segregation.

- Accurate proportioning and blending of aggregates additives for proper graded materials.

- Long life & guaranteed performance.